Wood-polymer composite products - high-margin products used in construction, automotive, industrial area

Wood-polymer composites (WPC) –are constructive and finishing materials with wide usage in building construction, machinery-building industry, furniture trade and other branches of industry.

Advantages of WPC in comparison with the materials that are normally used now (metal, wood, plastic):

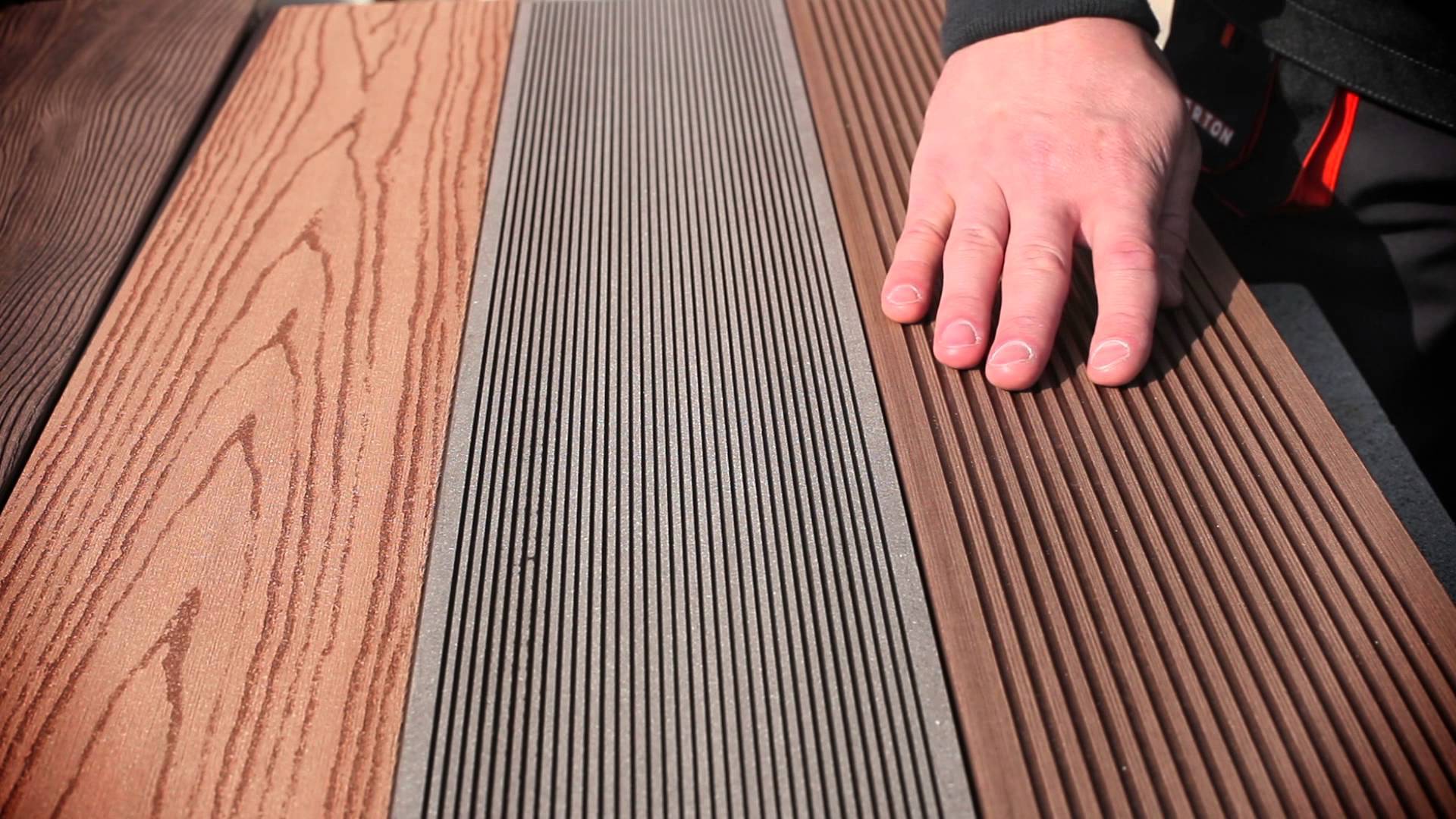

• elegant and detailed shape design,

• strength,

• safe to use for many years,

• no flammability,

• environmental friendliness,

• dimension stability against temperature difference, moisture, light, fungi, insects,

proof against dote and mold.

Fields of Application

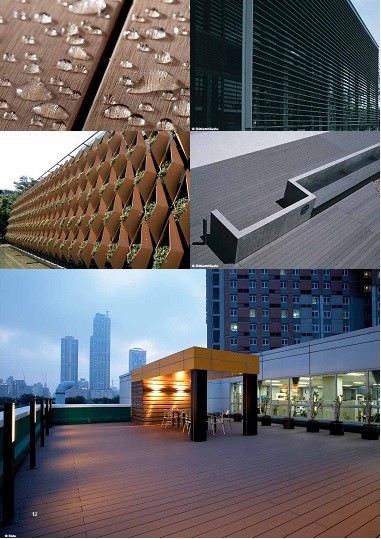

Building units: floor boards, balustrades, window and door frames, siding and accessories, fence board, roof coating.

Constructive units: foot pavements, piers, sea piles, bulkheads, banisters, railway units, noise barriers, timbering.

Automobile parts: inner panels, frames and roof gaskets, hubcaps for a spare wheel, casing, lifters, lorries’ floors, seat backs.

Industrial and consumers’ application: garden constructions, pallets, packages, equipment for sports grounds and children’s playgrounds, benches, tables, garbage boxes, guard rails, furniture and its elements, building.

Their high aesthetic qualities, the opportunity to fit directly on site the wide range of assembly units of different shapes and colors made of constructive units (railing, decking) and finishing materials (siding) – all this help to make unique the inner and outer finishing of buildings and to use them as whole architectural complex when building at grounds. WPC products have the face of wood and nature of plasticizer. They are easily machinable - they can be cut, drilled, flexed (when warmed-up). Unlike wood, they do not dote, get moldy and have a long term of life. WPC products’ long service, hazard resistance, profitability, safe usage, environmental friendliness – all this let to use these products for decoration of parks, embankments, yard grounds and others. Besides building, WPC products are widely used in automobile production and aircraft as finishing material for passenger compartments of autos and planes, and also they are used in furniture production.

Manufacturing

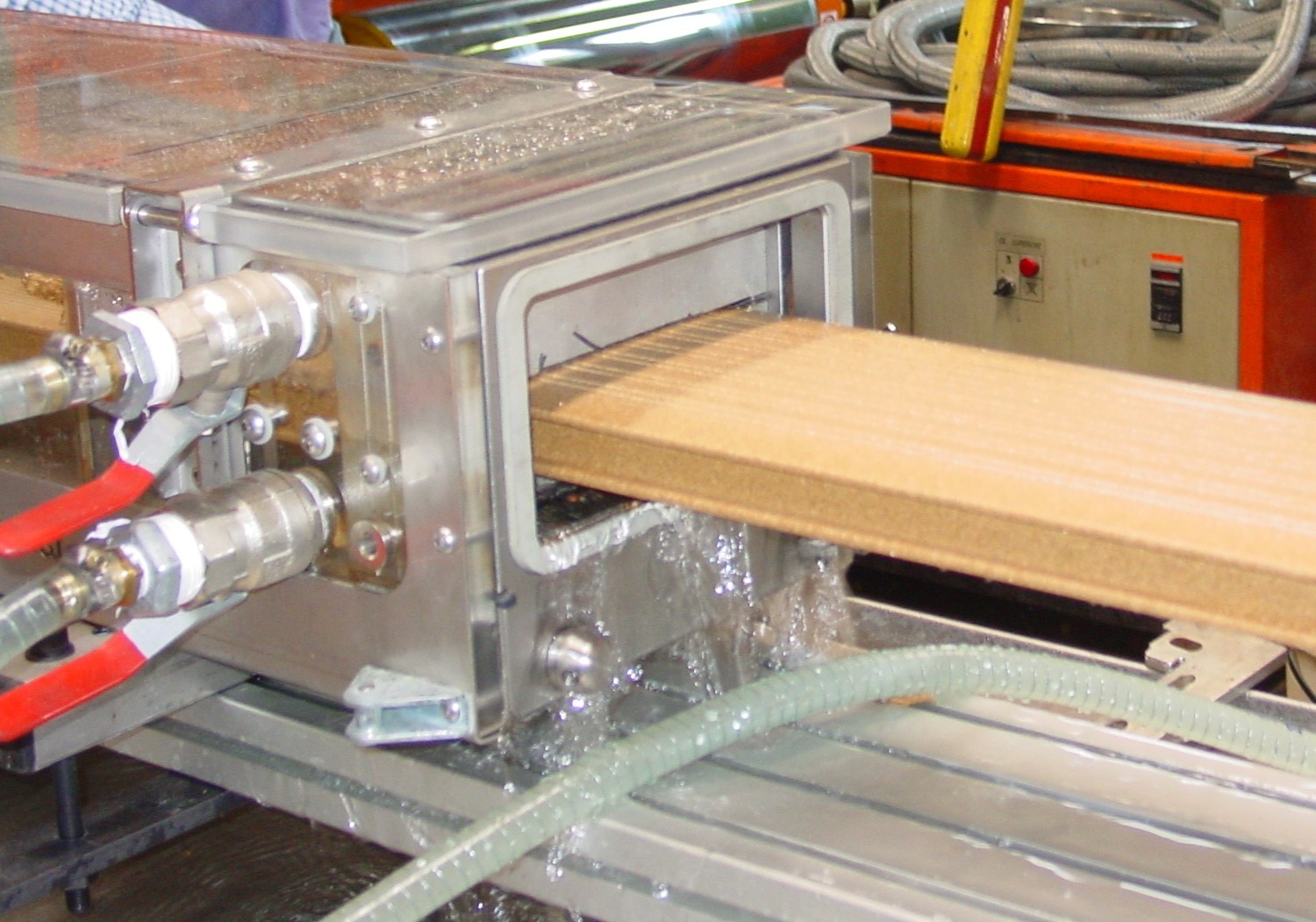

The basis of the production process is extrusion – that is extruding of the warmed-up plastic body through the extrusion devices. The warmed-up plastic body is a mixture of dosed elements such as filler (wood powder), polymeric material – plasticizer and additives.

The planned production is organized as a complex of independent single-purpose zones – wood powder preparation, mixing, extrusion of the plastic body and production of profiles at 10 - extrusion lines.

These zones and extrusion lines are mutually independent. In case if one of them is stopped by any reason (for maintenance, repair, renewing or equipment replacement), the rest of the lines continue working, this fact provides the flexibility of the production process.

Raw Material

- Thermofluid polymers, polyolifin - polyethylene, polypropylene;

- Filler – wood-working wastes (of hardwoods - birch, ash tree with density of 650 kg/m3.);

- Additives- binders, lubricating substances, light stabilizers, antipyrens (flameproofing initiators), antibacterial agents, anti-oxidizing agents and so on. The part of additives depends on the WPC composition and ranges from 5 to 10 %;

- Coloring agents- artificial highly-resistant colorants.

Market. Competitiveness

At present the Russian and world markets of WPC products are still in process. Due to the market research there are 14 potential target segments only 4 of which are developing nowadays. The rest of the segments are a reserve of the strategic development of the enterprise.

Favorable for the development of the market factors are measures on state regulation of the country's forestry complex, high potential of the consumer market, environmental initiatives for processing polymers, as well as the potential of the main consumer sectors: the construction industry (low-rise housing construction), the furniture industry, on Russian territory).

The product will have demand in the Russian market. When relevant geopolitical conditions, there will be an opportunity to sell the products on European and Asian markets.

The present project implementation will cause the development of import substitution and increase the export of Russian products that answers the purpose of the Russian program «The development of industry and increase of its competitiveness» approved by Russian Government Executive Order № 328 dated from April 15, 2014, and that is particularly topical at present geopolitical and geo-economical situation.

The project provides multiplicative effect that causes innovative developments of some branches of industry based on usage of new high-performance materials.

«SanWood»,LLC

Bld. 30, Galaktionovskaya Str, 443099 Samara, Russian Federation.

Политика конфиденциальности

Редактируемый текст

Данный сайт использует Cookie

Редактируемый текст